We also offer "Dry Fog" type dust suppression system which is particularly suitable for enclosed material handling plants where the addition of moisture has to be kept to an absolute minimum. This method uses water and compressed air to make micron sized water droplets that are able to suppress respirable dust without adding any detectable moisture to the process..

Air assisted atomizing nozzles:

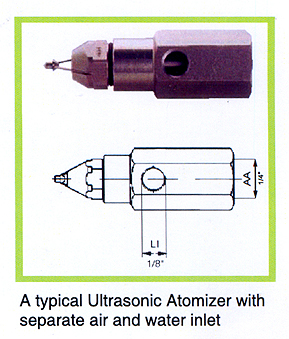

We use ultrasonic atomizers which atomizes the liquid using a compressed air supply that is capable of producing extremely fine droplets. Ultrasonic atomizer works through a two-step process:

Step 1: Liquid is injected through a number of small orifices into the nozzle outlet channel, where a high velocity air stream provides the first liquid breakup.

Step 2: The air stream carrying the droplets impacts onto a resonator placed in front of the nozzle outlet orifice, generating a field of high frequency sound waves. Flying through the sound wave field, the droplets undergo an additional breakup step.